Sponsored article

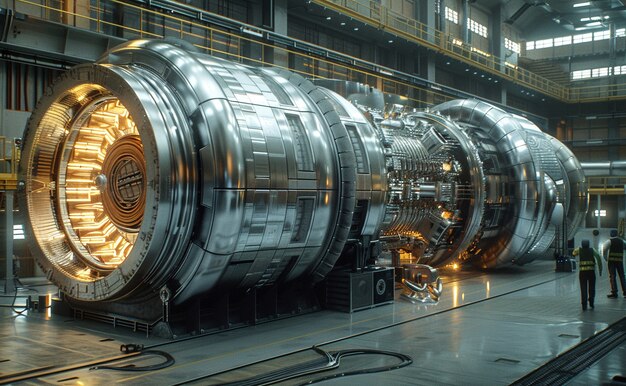

All those who operate or manage ships understand the significance of efficient functioning in maritime vehicles. At the heart of a ship’s operational performance lies its propulsion system, the driving force that keeps the ship moving. Regular maintenance of this vital system doesn’t just ensure optimum performance but also extends the system’s lifespan and decreases downtime. This article shines light on the importance of continuous maintenance of a ship’s propulsion system and how it translates to overall improved ship performance.

The efficacy of a ship hinges largely on the performance of its propulsion system. Coupling paramount ship performance with consistent and thorough propulsion system maintenance is crucial. Offering comprehensive services in this area, BOTA TECHNIK emphasizes the profound correlation between these two elements. Through regular maintenance, potential issues are preemptively identified and corrected, ensuring:

Consequently, such maintenance directly impacts ship performance by minimizing falter potential and ensuring uninterrupted, seamless voyages. Equipping ships with an impeccable propulsion system through diligent regular maintenance, BOTA TECHNIK’s key strategy, leads to operational excellence and industry precedence.

Continuous maintenance plays a pivotal role in enhancing the propulsion system lifespan of a ship. By adhering to regular inspection and check-ups, unwanted breakdowns and mishaps in the long run can be prevented, providing longevity to the system. Such straightforward practices can result in major cost savings and a pronounced increase in efficiency over time.

Upkeep tasks range from simple system check-ups to detailed inspections of each part, ensuring that problems are identified and corrected promptly. The result is an extended propulsion system lifespan, improving the overall ship performance. Understanding and applying the concept of continuous maintenance is therefore essential for any successful maritime operation.

An unattended propulsion system on commercial shipping vessels presents significant detriments to operational efficiency. With no maintenance strategy applied, the system succumbs to inevitable wear and tear, leading to unexpected downtime. The downtime can cause disproportionate delays in sailing schedules, often with severe financial implications.

More concerning, however, are the soaring repair costs associated with neglecting regular maintenance. Overhauling an overlooked system not only requires complex service but also necessitates replacement of damaged parts – a hefty expense that could be substantially reduced with routine checks. Therefore, comprehending the impacts of unattended propulsion systems on downtime and repair costs is integral to achieving efficient ship performance.